Essentially polyester is a man-made synthetic plastic resin substance. Polyester can be produced in sheet form, for items like PET bottles, or fibre form for all kind of textiles.

Polyester fabrics are heat sensitive and can be manipulated with high heat and pressure such as giving the fabric permanent pleats, laser cut with patterns and shapes. Polyester fibres can be produced in various forms allowing the manufactured fabric to imitate characteristics of fabrics traditionally produced in natural fibres.

Polyester fabrics are highly stain resistant and there is only one particular type of dyes that can alter the colour or polyester fabrics, known as disperse dyes. While these dyes can be applied to the fabric in several ways, the most common way is by dye-sublimation. Dyes are printed onto a paper substrate which is then pressed into the fabric using high temperatures and pressure. The pressing process bonds the dyes to the polyester fibres of the fabric meaning that they will never fade or wear.

Polyester fibres can also be recycled, using less energy than virgin polyester and less water than organic natural fibre production, which leads to some considering recycled polyester (rPET) a sustainable fabric for future generations. The fabric printing method of dye-sublimation is a completely dry process has no water usage and while the paper is a waste by product, all dye is absorbed by the fabric leaving no dye waste.

Natural fabric is woven or knitted from fibres that occur in our natural world. All three sectors of nature; animal, vegetable and mineral produce fibres that can be used in fabric production.

Vegetable, or more commonly classed cellulose-based fibres, include cotton, flax, jute, hemp and bamboo. Each fibre type is derived from a specific part of the plant such seed hair, stem, leaf, husk etc. and consist mainly of cellulose substance.

Animal fibres include wool and silk and consist exclusively of proteins. While wool fabric is most commonly produced from the fleece of sheep, it also includes fleece from alpacas. The hairs or fibres of other animals are also constructed into fabric including rabbit fur, angora fabric and mohair.

Silk is the other notable fibre from an animal, but unlike other animal fibres, it is not made from the hair or fur covering the animal. It is the continuous thread of the spun cocoon of moth larvae. An extensive process is required to produce one silk fibre and in turn, produce silk fabric maintaining its exclusive divine nature.

Mineral fibres are less widely used in production for fashion or interior fabrics but can still be used in an industrial application. Fine drawn threads of metallic fibres can be used on regular textile machinery and are often spun or woven in combination with other fibres to make a length of fabric for industrial use.

Essentially polyester is a man-made synthetic plastic resin substance. Polyester can be produced in sheet form, for items like PET bottles, or fibre form for all kind of textiles.

Polyester fabrics are heat sensitive and can be manipulated with high heat and pressure such as giving the fabric permanent pleats, laser cut with patterns and shapes. Polyester fibres can be produced in various forms allowing the manufactured fabric to imitate characteristics of fabrics traditionally produced in natural fibres.

Polyester fabrics are highly stain resistant and there is only one particular type of dyes that can alter the colour or polyester fabrics, known as disperse dyes. While these dyes can be applied to the fabric in several ways, the most common way is by dye-sublimation. Dyes are printed onto a paper substrate which is then pressed into the fabric using high temperatures and pressure. The pressing process bonds the dyes to the polyester fibres of the fabric meaning that they will never fade or wear.

Polyester fibres can also be recycled, using less energy than virgin polyester and less water than organic natural fibre production, which leads to some considering recycled polyester (rPET) a sustainable fabric for future generations. The fabric printing method of dye-sublimation is a completely dry process has no water usage and while the paper is a waste by product, all dye is absorbed by the fabric leaving no dye waste.

Natural fabric is woven or knitted from fibres that occur in our natural world. All three sectors of nature; animal, vegetable and mineral produce fibres that can be used in fabric production.

Vegetable, or more commonly classed cellulose-based fibres, include cotton, flax, jute, hemp and bamboo. Each fibre type is derived from a specific part of the plant such seed hair, stem, leaf, husk etc. and consist mainly of cellulose substance.

Animal fibres include wool and silk and consist exclusively of proteins. While wool fabric is most commonly produced from the fleece of sheep, it also includes fleece from alpacas. The hairs or fibres of other animals are also constructed into fabric including rabbit fur, angora fabric and mohair.

Silk is the other notable fibre from an animal, but unlike other animal fibres, it is not made from the hair or fur covering the animal. It is the continuous thread of the spun cocoon of moth larvae. An extensive process is required to produce one silk fibre and in turn, produce silk fabric maintaining its exclusive divine nature.

Mineral fibres are less widely used in production for fashion or interior fabrics but can still be used in an industrial application. Fine drawn threads of metallic fibres can be used on regular textile machinery and are often spun or woven in combination with other fibres to make a length of fabric for industrial use.

Through dealing with a lot of creatives we came to realise that some are having difficulties on setting up their artwork digitally into a seamless repeat, so we decided to help and after research we have put together a small collection of useful tutorials in Photoshop and Illustrator. So if you are trying to wrap your head around repeating pattern, these are for you.

- A Beginner’s Guide to Digital Textile Printing (from Design.tutsplus.com)

//design.tutsplus.com/tutorials/a-beginners-guide-to-digital-textile-printing–vector-3189

//design.tutsplus.com/tutorials/a-beginners-guide-to-digital-textile-printing–vector-3189

- How to make a Repeat Pattern (from DesignSponge.com)

//www.designsponge.com/2008/05/welcome-julia-and-how-to-make-a-repeat-pattern.html

//www.designsponge.com/2008/05/welcome-julia-and-how-to-make-a-repeat-pattern.html

- Exploring Photoshop: Designing Repeat Patterns (from Creative-Cloth.com)

//www.creative-cloth.com/photoshop-elements-tutorial-designing-repeat-patterns/

//www.creative-cloth.com/photoshop-elements-tutorial-designing-repeat-patterns/

- Adobe Illustrator for Fashion and Textile design: Print for flat sketch (from Fashion Chalkboard)

Part 1: https://www.youtube.com/watch?v=5HalcOTtxgo

Part 1: https://www.youtube.com/watch?v=5HalcOTtxgo

Part 2: https://www.youtube.com/watch?v=QFV68tAi88k

- Create beautiful repeating Patterns (from DigitalArtsOnline.co.uk)

//www.digitalartsonline.co.uk/tutorials/illustration/create-beautiful-repeating-patterns/

//www.digitalartsonline.co.uk/tutorials/illustration/create-beautiful-repeating-patterns/

Through dealing with a lot of creatives we came to realise that some are having difficulties on setting up their artwork digitally into a seamless repeat, so we decided to help and after research we have put together a small collection of useful tutorials in Photoshop and Illustrator. So if you are trying to wrap your head around repeating pattern, these are for you.

- A Beginner’s Guide to Digital Textile Printing (from Design.tutsplus.com)

//design.tutsplus.com/tutorials/a-beginners-guide-to-digital-textile-printing–vector-3189

//design.tutsplus.com/tutorials/a-beginners-guide-to-digital-textile-printing–vector-3189

- How to make a Repeat Pattern (from DesignSponge.com)

//www.designsponge.com/2008/05/welcome-julia-and-how-to-make-a-repeat-pattern.html

//www.designsponge.com/2008/05/welcome-julia-and-how-to-make-a-repeat-pattern.html

- Exploring Photoshop: Designing Repeat Patterns (from Creative-Cloth.com)

//www.creative-cloth.com/photoshop-elements-tutorial-designing-repeat-patterns/

//www.creative-cloth.com/photoshop-elements-tutorial-designing-repeat-patterns/

- Adobe Illustrator for Fashion and Textile design: Print for flat sketch (from Fashion Chalkboard)

Part 1: https://www.youtube.com/watch?v=5HalcOTtxgo

Part 1: https://www.youtube.com/watch?v=5HalcOTtxgo

Part 2: https://www.youtube.com/watch?v=QFV68tAi88k

- Create beautiful repeating Patterns (from DigitalArtsOnline.co.uk)

//www.digitalartsonline.co.uk/tutorials/illustration/create-beautiful-repeating-patterns/

//www.digitalartsonline.co.uk/tutorials/illustration/create-beautiful-repeating-patterns/

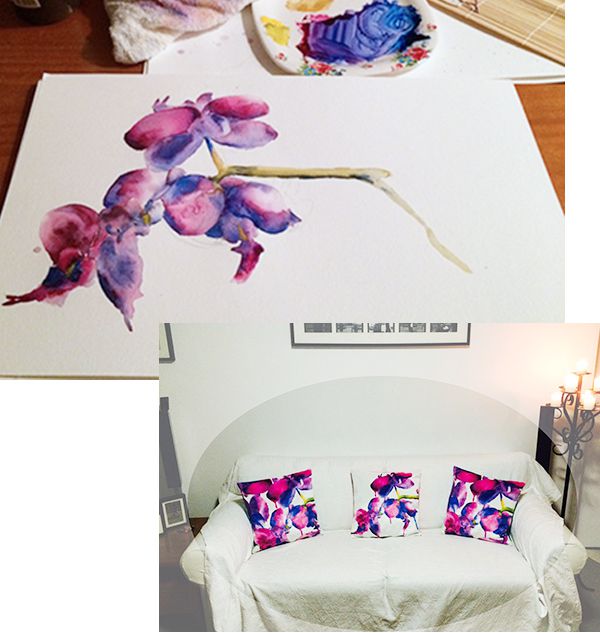

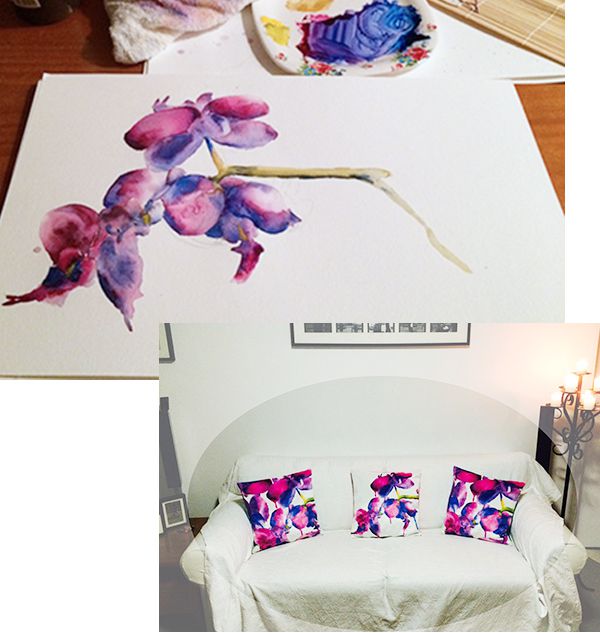

Interested on how to make your custom cushions?

Here are some helpful steps on how to set up your artwork ready to print with us.

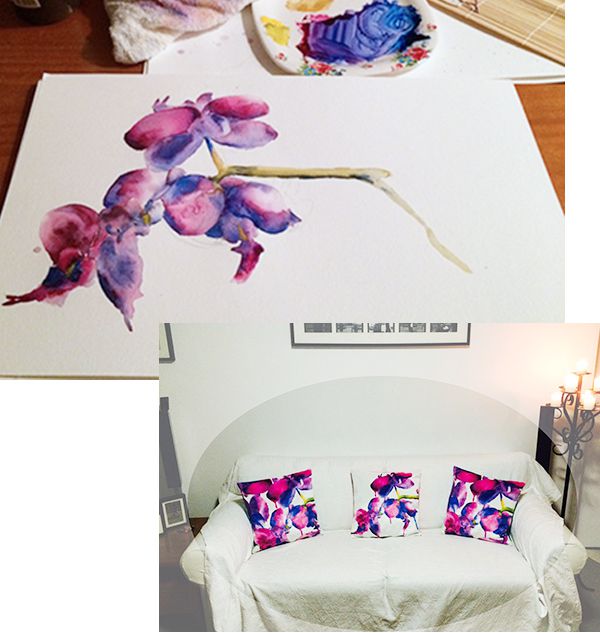

You can print custom cushions from any type of design photographic, hand drawn/painted, created in Photoshop or Illustrator, the possibilities are endless! Any size, any shape, front and back or just front panels of cushions.

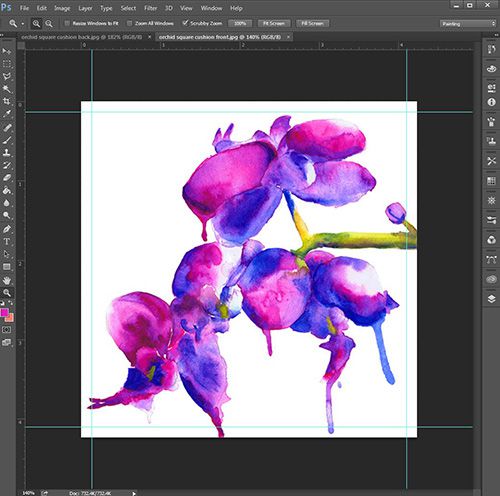

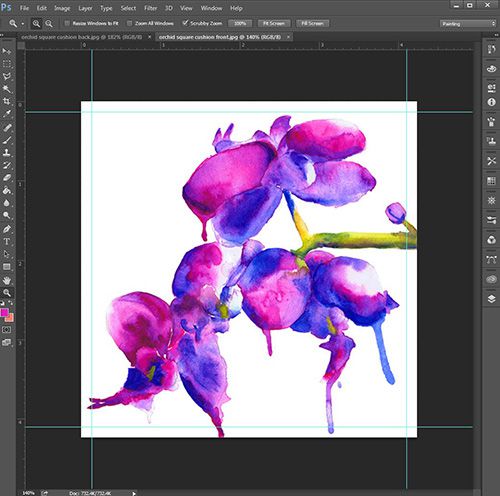

For this how-to we chose to paint beautiful Orchids in watercolour. Once painting is finished and dry we digitized the artwork by scanning it at high dpi of 300, artwork also can be photographed.

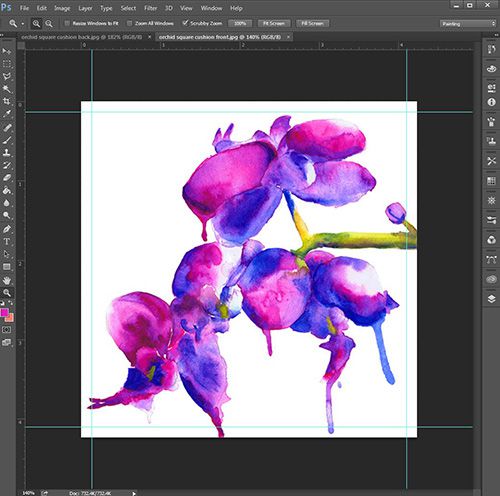

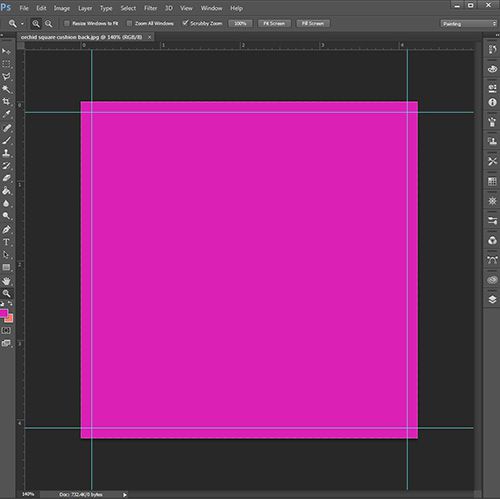

After artwork is scanned and manipulated to desired colour and placement create a new canvas in RGB colour mode, 48 x 48 cm for finished size cushion cover of 45cm x 45cm including 1.5cm seam allowance on all sides of the cushion covers.

To help remember that there is seam allowance on the artwork put guidelines on all sides 1.5cm in (these guidelines won’t show when printed). Place an artwork on art board, play around with the placement until you get the look you are after and be mindful that anything outside of the guidelines will not be seen. We print digitally onto white fabric, for this specific cushion we wanted a white background so we left the background white, if you want a colour background you can do so by creating a new layer with the colour and placing it behind the artwork.

When you are happy with the results you can flatten your artwork and save, artwork can be saved as either a JPEG or TIFF.

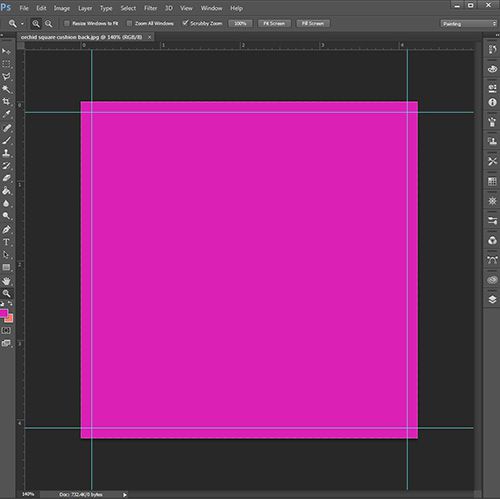

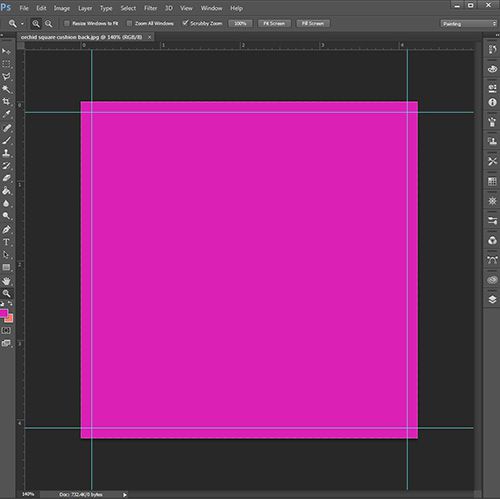

Repeat these steps for the back of the cushion cover, if you want a certain colour for the back, drop in the colour you want into the layer.

Once all is in order and your order is ready to proceed leave it to us and we can do the rest, your cushion covers will be done in no time.

We hope this helps you on your way to creating some amazing custom cushion covers to spice up your home.

Happy Designing!

The Digital Fabrics Team

Save

Save

Save

Interested on how to make your custom cushions?

Here are some helpful steps on how to set up your artwork ready to print with us.

You can print custom cushions from any type of design photographic, hand drawn/painted, created in Photoshop or Illustrator, the possibilities are endless! Any size, any shape, front and back or just front panels of cushions.

For this how-to we chose to paint beautiful Orchids in watercolour. Once painting is finished and dry we digitized the artwork by scanning it at high dpi of 300, artwork also can be photographed.

After artwork is scanned and manipulated to desired colour and placement create a new canvas in RGB colour mode, 48 x 48 cm for finished size cushion cover of 45cm x 45cm including 1.5cm seam allowance on all sides of the cushion covers.

To help remember that there is seam allowance on the artwork put guidelines on all sides 1.5cm in (these guidelines won’t show when printed). Place an artwork on art board, play around with the placement until you get the look you are after and be mindful that anything outside of the guidelines will not be seen. We print digitally onto white fabric, for this specific cushion we wanted a white background so we left the background white, if you want a colour background you can do so by creating a new layer with the colour and placing it behind the artwork.

When you are happy with the results you can flatten your artwork and save, artwork can be saved as either a JPEG or TIFF.

Repeat these steps for the back of the cushion cover, if you want a certain colour for the back, drop in the colour you want into the layer.

Once all is in order and your order is ready to proceed leave it to us and we can do the rest, your cushion covers will be done in no time.

We hope this helps you on your way to creating some amazing custom cushion covers to spice up your home.

Happy Designing!

The Digital Fabrics Team

Save

Save

Save

We have to admit we love DIY’s and what better than a DIY using our fabric’s. We found this tutorial on how to make your own lampshade and we are excited to try it out.

DIY lampshade Ohoh-blog.blogspot.com

Now we just have to decide which fabric to choose, here is an idea using prints from out print collection. All prints are now available to be printed on our stock fabrics, you can check out all our designs on our website.

DIY lampshade idea with DF design applied

Images: Ohohblog.com and Pinterest.

We have to admit we love DIY’s and what better than a DIY using our fabric’s. We found this tutorial on how to make your own lampshade and we are excited to try it out.

DIY lampshade Ohoh-blog.blogspot.com

Now we just have to decide which fabric to choose, here is an idea using prints from out print collection. All prints are now available to be printed on our stock fabrics, you can check out all our designs on our website.

DIY lampshade idea with DF design applied

Images: Ohohblog.com and Pinterest.